Removes surface defects such as scratches, swirls, water spots, and much more from your vehicle’s paint using the best polishes, and techniques. Experience is what separates us from other shops. Decontamination of the paint in the wash phase is the most important part of the process before any machine touches any surface. No paint is the same, and different types of paint systems require a more methodical approach to finishing correctly.

The automotive paint correction process includes a multi-step chemical decontamination wash, a synthetic clay bar exfoliating treatment, and a color refining machine polish that enhances gloss & removes surface defects using a machine polisher and strategically selected pads and compounds based on the type and condition of the paint.

Proper paint correction varies vehicle to vehicle and in some cases panel to panel on the same vehicle due to a lot of variables such as severity of the defects, hardness/softness of the paint, original vs repainted panels and even color of the paint.

STARTING AT

Coupe: $450

Midsize: $650

Truck/Van $800

Taking the time to evaluate a vehicle’s condition is never overlooked when accepting a job for service. Before we begin, it’s important to do a thorough walk-around and visually inspect the surface of the car. Measurements are also necessary using a paint gauge to check clear coat.

It’s important to know if a panel has previously been repainted and the types of defects that will be encountered during service. By doing this, we will know in advance if the job will be more complex than simply just accepting the job and later running into issues.

After assessing the condition of your vehicle, a set of pads and polishing cream will be used for the test spot. Moreover, by doing the test spot, we will be able to see how the paint reacts when polishing. This will determine which course of action to take moving forward.

Before beginning any machine polishing, it’s crucial to evaluate the level of clear coat we will be working with. The paint gauge will tell us the thickness of the clear coat on any given surface, so we can remove defects safely and effectively without damaging the paint.

One thing to keep in mind, however, is that if certain areas of the paint read 6 mils or more, indicates a repainted panel. You can usually confirm this by feeling for overspray on the edges of the panels or keeping an eye out for orange peel. Most factory paint ranges from 4 to 5 mils, but a thinner reading could indicate that the clear coat has been almost entirely removed.

If you’re dealing with a vehicle that is dark in color, especially non-metallic black, and has a soft clear coat. A thickness of 3.0 mils or less is not uncommon. Aggressive machine-polishing could surely result in burning through the paint.

Filling in rock chips on a vehicle’s paint job can make a big difference in its overall appearance. Our shop will have your bottle of touch up paint mixed from a company called Scottsdale Paint & Supply. Never have we had any issues with matching paint.

Regarding taking care of rock chips on the vehicle, it’s important to follow a specific process to guarantee the best results. First, the area with the rock chips will be machine polished before applying touch-up paint. It’s crucial to clean the chips using isopropyl alcohol and fill them in with touchup paint. After waiting about 10-20 minutes, a leveling aid will be used to blend the areas around the chips.

Metallic paint has long been known as a durable and strong clear-coat option. Paint correction, ceramic coating, and other related services all work better with a metallic finish.

Its harder surface takes the necessary polishing procedures better than standard non-metallic paint systems. The extra shine of metallic adds an extra dimension to the car that increases its overall look exponentially. A single or two-stage paint correction is usually the best option.

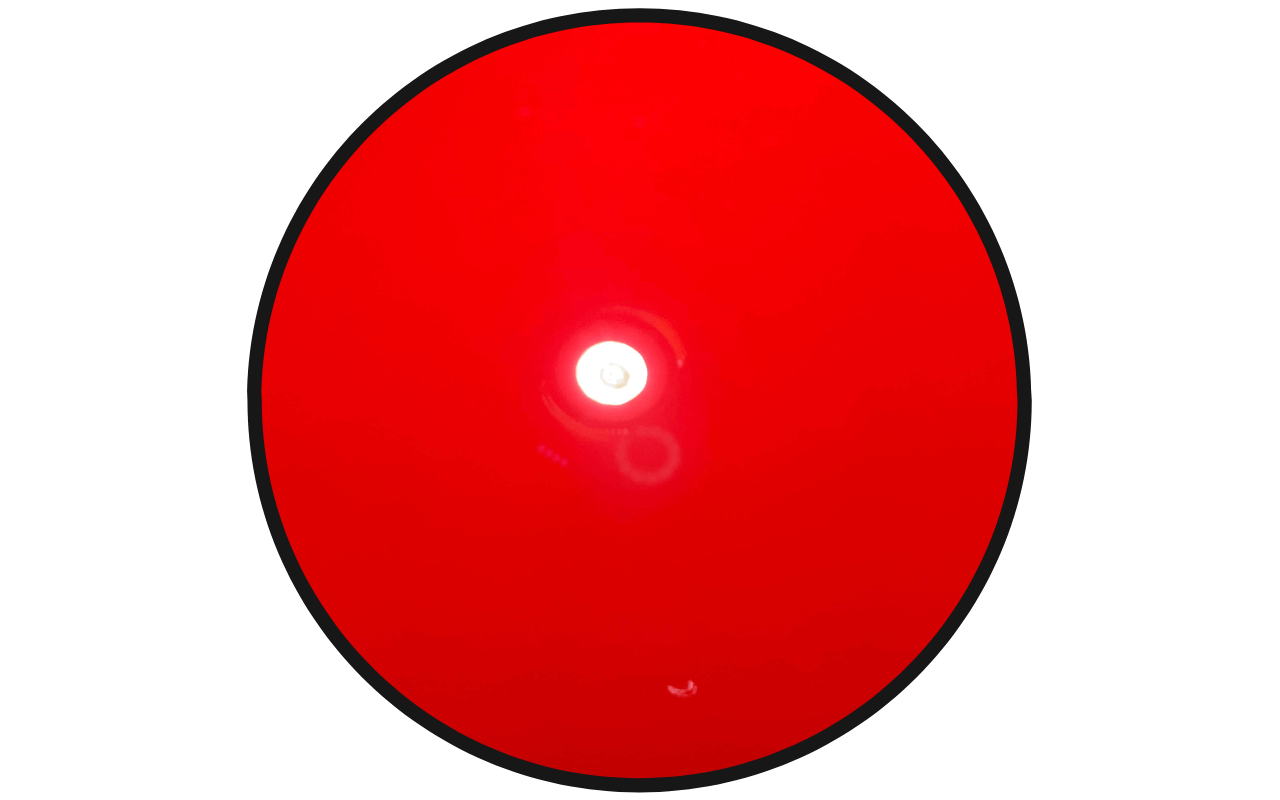

Paint that shows no metallic typically has a softer, more translucent clear coat than metallic or matte varieties. While this may provide a unique and appealing finish, it also makes the painted surface much more prone to scratches and marks.

Ceramic coating installation can be more difficult to level due to the nature of soft clearcoat. Plush microfiber towels are necessary to avoid light scratches from removing ceramic coating. Non-metallic paint requires a two-stage paint and sometimes three-stage paint correction to properly remove defects.

Non-metallic, soft dark colored paint can be a real pain regarding restoration. Its softness makes it susceptible to scratches, which makes the restoration process more challenging.

It's important to bear in mind that the soft nature of this paint makes it more prone to a controlled defects called micro-marring. Installing a ceramic coating on this paint can be more difficult to work with.

We have to take a more gentle approach by using plush microfiber towels when wiping away any leftover coating residue. Additionally, maintenance of the paint should be as gentle as possible to avoid scratching. This type of paint is more prone to wash-induced swirl marks and other damage.

Compact Vehicle – $450

Full Size Vehicle – $550

Oversize Vehicle – $650

Compact Vehicle – $650

Full Size Vehicle – $750

Oversize Vehicle – $850

Compact Vehicle – $800

Full Size Vehicle – $1000

Oversize Vehicle – $1500

Polishing soft/dark colored clear-coat

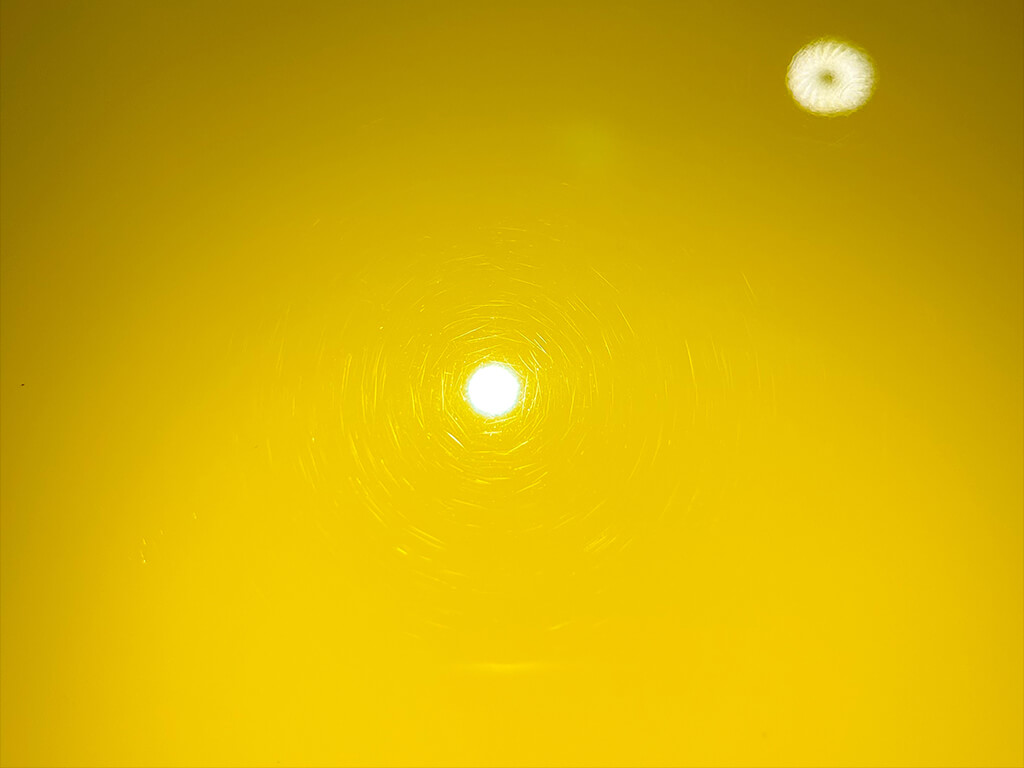

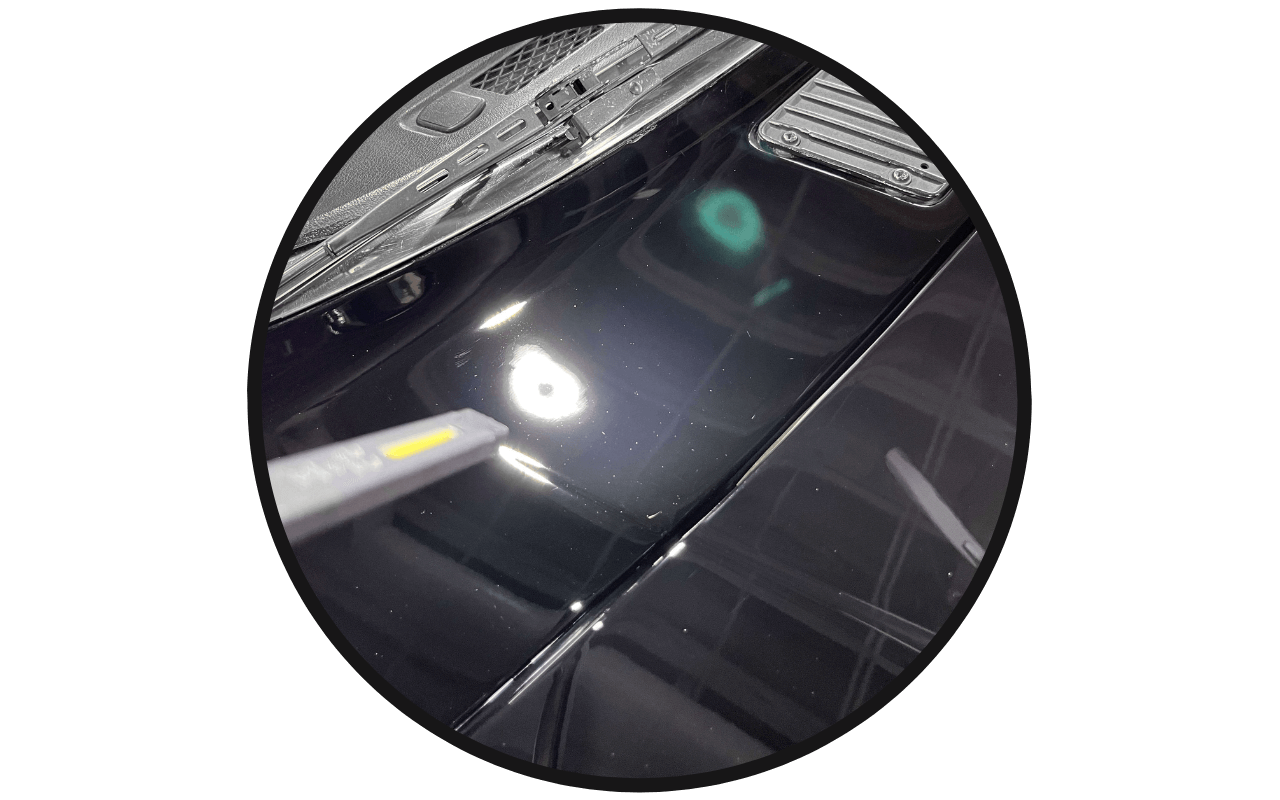

The first picture captures a frustrating reality for many car owners – random isolated deep scratches and swirl marks. A variety of things, from accidental scrapes to the harsh brushes of a car wash, can cause these defects.

However, the challenge is amplified for those with soft dark-colored paint, as the scratches and swirls are more noticeable. In cases like these, a three-stage paint correction is necessary to restore the car’s untarnished appearance. The first stage will require a microfiber pad and heavy cutting polish to remove the defects.

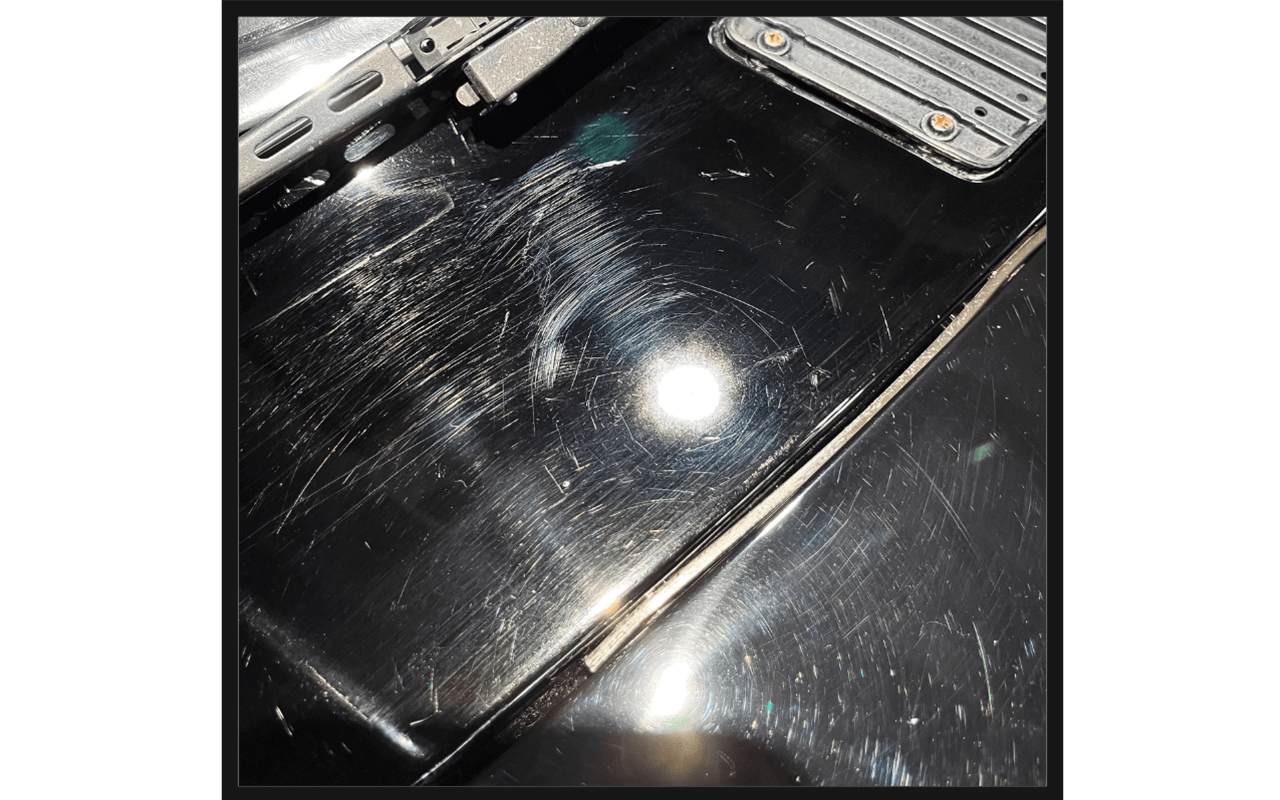

This is a controlled defect from the polishing process, where the combination of a dual action polisher, a microfiber pad, and heavy cutting polish leads to the creation of a subtle, uniform haze on the vehicle’s paintwork.

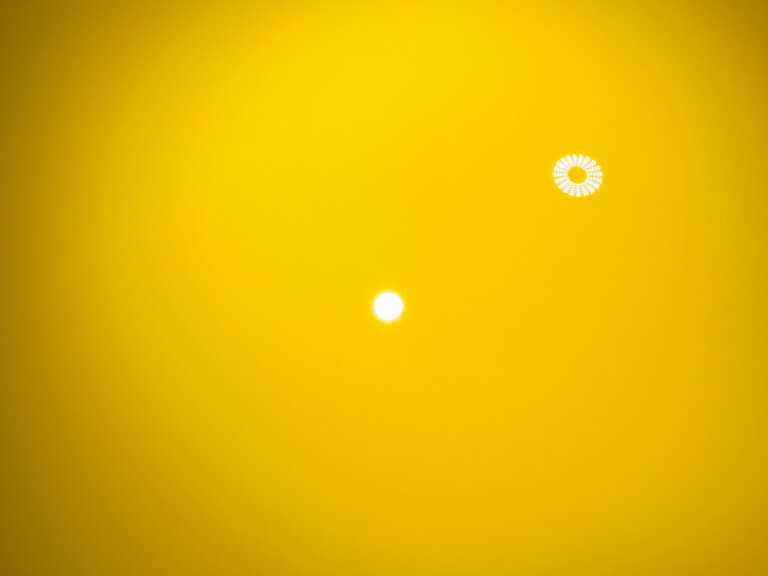

The necessity and extent of paint correction depend on the severity of the micro-marring affecting your car’s finish. Vehicles with lighter colored metallic paint often require just a single or two-stage paint correction process. Metallic paints, being more durable, are better suited to withstand aggressive polishing without succumbing to micro-marring.

For visitors seeking solutions and insights into paint correction, particularly for dark-colored cars, understanding these nuances is crucial. Darker cars can truly shine with the right paint correction approach, skillfully removing micro-marring, and revealing a flawless finish.

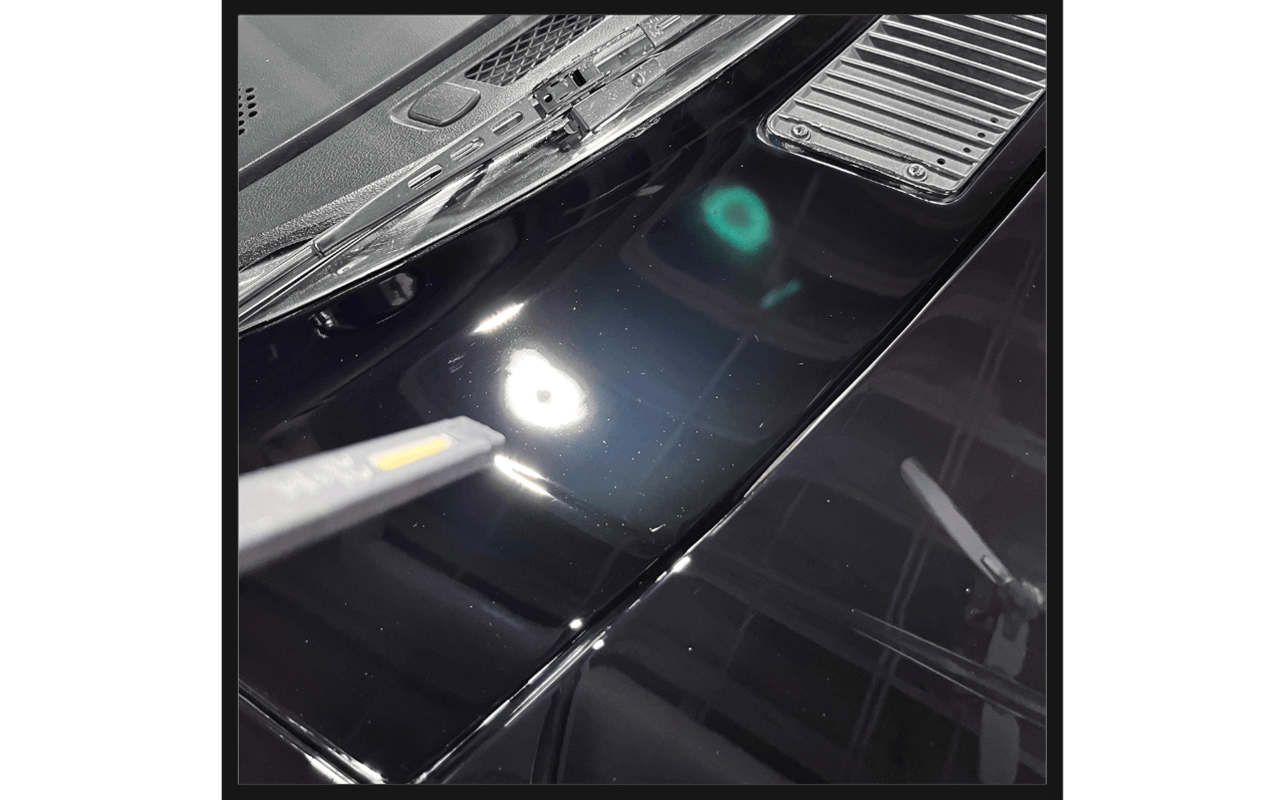

After completing the first stage of polishing to remove larger imperfections, the next step is to move onto the second stage to tackle micro-marring. This process involves using a medium cutting polish in combination with a less dense foam pad.

The medium polish is designed to remove fine scratches and swirls, while the less dense foam pad allows for a gentler application, preventing any further micro-marring to the paint. This stage of polishing can be time-consuming.

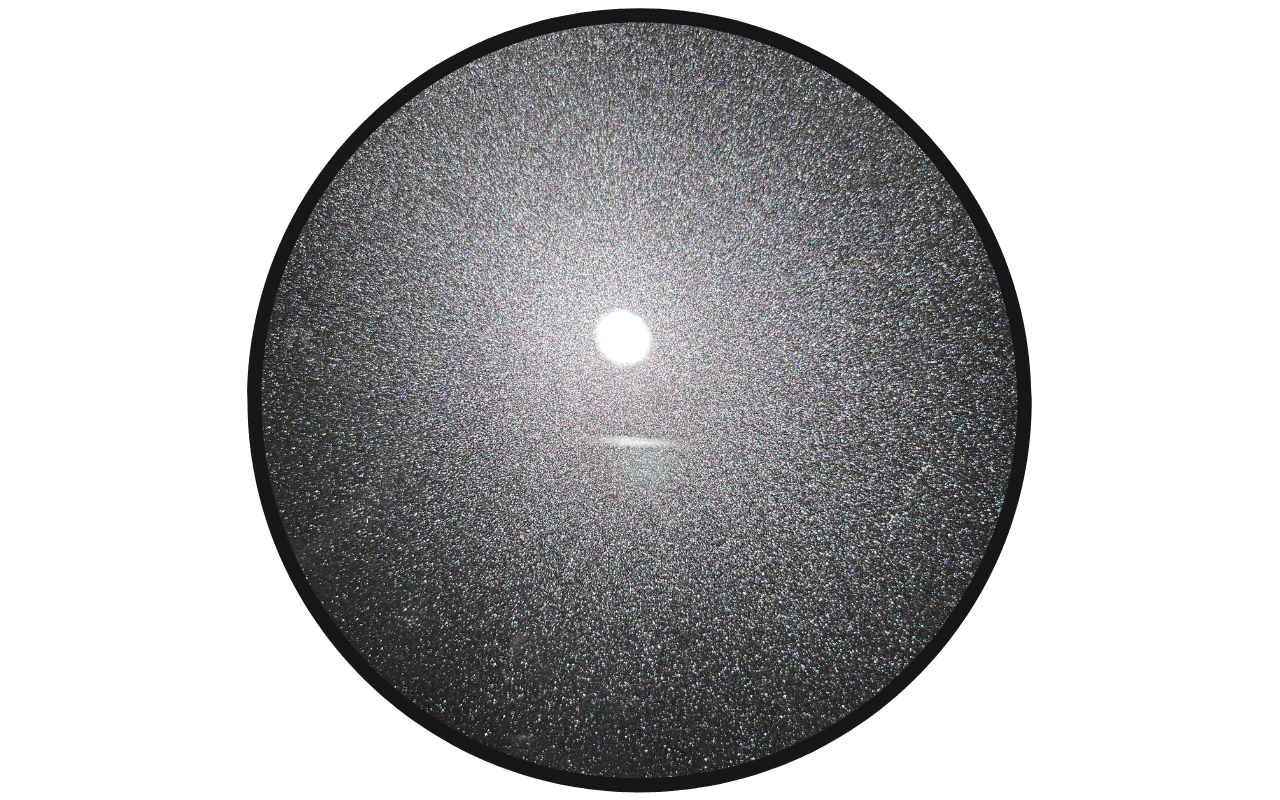

Achieving a pristine, mirror-like finish on a vehicle’s paintwork is a meticulous process that requires attention to detail and a carefully selected set of tools. In the final stage of polishing, an extremely fine polish and non-abrasive foam pad are used to remove any leftover imperfections and micro-marring for a flawless, defect-free surface.

This step guarantees the desired results of clarity, reflection, gloss, and deep shine. The level of dedication required in this process is a testament to the high standards expected in the automotive detailing industry. A perfect finish on a vehicle is a sight to behold, sure to impress even the most discerning of enthusiasts.

Paint checking is a common below surface paint defect that occurs when a concentrated amount of small cracks form within the paint. Over time checking can become more prominent and affect the overall appearance of the painted surface.

The causes of paint checking can be varied, and include factors such as poor factory paint, super low quality, rushed prep work, and materials used were poor quality to begin with. There is no fix regarding paint correction for paint checking because of its paint failure. The only solution would be to repaint areas with this defect or wet-sand and install vinyl wrap.

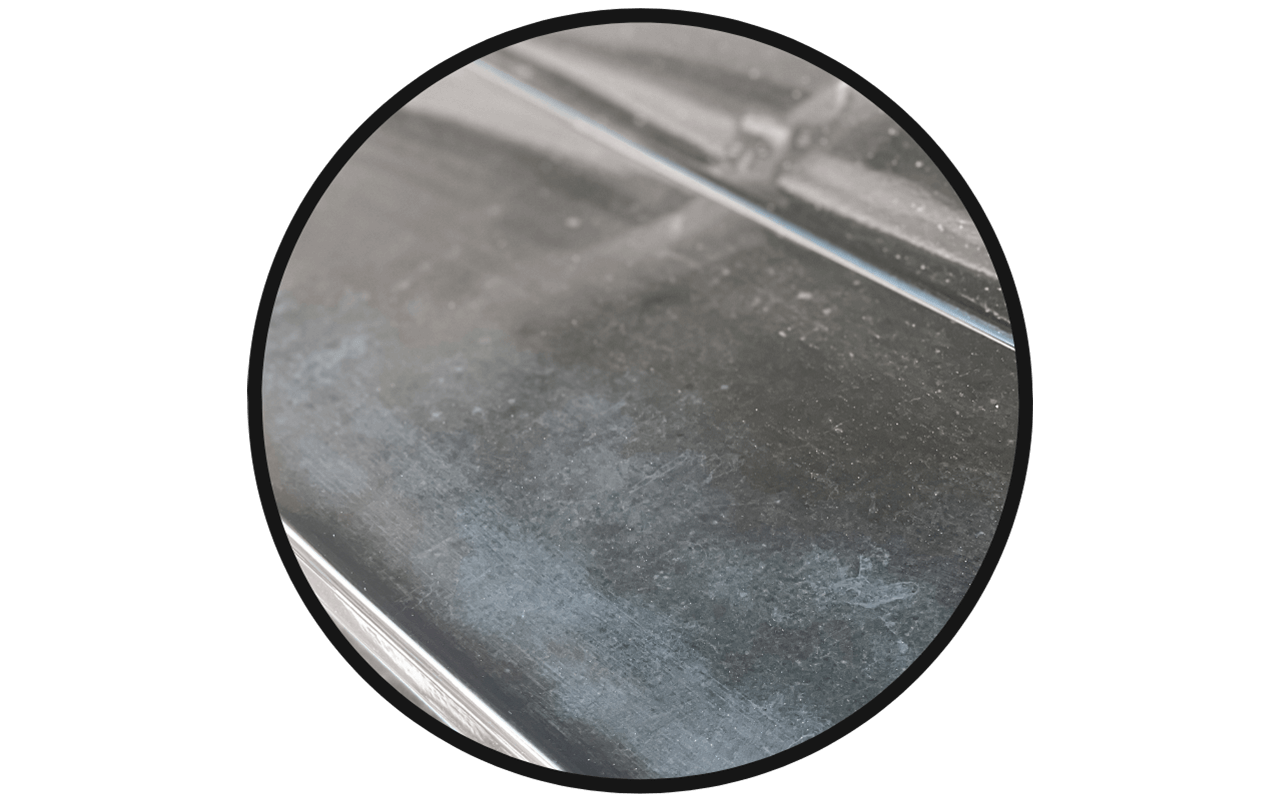

Regarding the longevity of your vehicle’s clear-coat, paint oxidation can be a real issue. This phenomenon occurs in either the clear coat or base coat level of the paint and is primarily caused by prolonged exposure to the sun's UV rays.

Over time, this exposure causes the protective layer of the paint to break down and lose its sheen, resulting in a dull and lackluster appearance.

Paint correction may be able to fix this issue, but paint oxidation symptoms are signs that total paint (clear coat) failure have already taken place. The only solution would be to repaint areas with this defect or wet-sand and install vinyl wrap.

These unsightly abrasion defects occur when an object rubs or collides with the surface of a vehicle, leaving behind a visible mark that can detract from the overall appearance of the car.

While some may dismiss these marks as a minor cosmetic issue, and sometimes can be fixed with touch-up paint. Usually paint transfer or scuffs require a repainting of the surface.

We understand you may have questions about maintaining your vehicle’s aesthetic appeal through paint correction. Here are answers to some of the most common queries we receive to help you understand our process and what to expect.

Maintaining your vehicle paint requires a combination of regular washing, applying a suitable protectant, and avoiding exposure to harsh environmental elements as much as possible. After paint correction, we recommend a schedule of weekly washes using a pH-neutral car shampoo and microfiber cloths to prevent dirt build-up.

Applying a high-quality wax or sealant every three to four months will also protect the paint from UV rays and contamination. Parking in the shade or using a car cover can further protect the paint from sun damage.

Paint correction is a thorough process aimed at restoring and rejuvenating the vehicle's paint surface. It typically involves a detailed assessment of the paint's condition, followed by a series of steps to remove swirl marks, scratches, oxidation, and other imperfections. The process may include:

Each paint correction service is tailored to the specific condition of your vehicle’s paint and desired outcome.

The time required for full paint correction can vary significantly based on the vehicle's size, paint condition, and the level of correction desired. On average, a full paint correction process can take anywhere from 5 to 20 hours.

For more precise timelines, we evaluate each vehicle on a case-by-case basis to provide a more accurate estimate. Remember, achieving a flawless finish requires patience and attention to detail, so it’s well worth the investment of time.

Yes, paint correction is highly recommended before applying a ceramic coating. Ceramic coatings seal the paint, locking in its current condition. Performing paint correction beforehand ensures that the paint surface is as flawless as possible, resulting in a stunningly glossy and protected finish.

Applying ceramic coating without correcting the paint first would seal in imperfections, detracting from your vehicle’s appearance and potentially making them more noticeable. We hope these answers help clarify some of your queries about paint correction. If you have more questions or would like to schedule a consultation, please don't hesitate to contact us.